Hey everyone! It’s been a while since my last update, and my plans have shifted a bit, so I wanted to share my current goals and progress.

Learning the Art of Electronics (LAOE)

Many of you have likely heard of this classic book (and its parent, “The Art of Electronics”). To strengthen my fundamental understanding of electronics, I’m working my way through LAOE and completing the accompanying labs. At the end of each chapter, I’ll build a small circuit or project to apply what I’ve learned and hone my design skills. I feel this approach is important because I often find myself limited by my knowledge of basic components in my larger projects. The hands-on labs and projects in LAOE are a major plus for me.

Currently, I’m reading Day 3’s material and aim to finish it by the end of next week. My plan is to complete one chapter every two weeks until winter, then ramp up to one chapter per week during the colder months. This schedule should have me finishing the book in March – right before my birthday! I’m taking a slightly slower pace to ensure I have time to experiment and really understand the different components.

Here’s a quick recap of what I’ve covered so far:

Chapter 1/Day 1

Focused on DC circuits, building voltage dividers, discussing resistor types, and getting familiar with measurement tools (oscilloscopes, etc.). I practiced using my Analog Discovery 3, which was helpful even for familiar concepts. I also built a simple project (a circuit to monitor voltage and current across a device) to create a V-I curve, as described in the book.

Chapter 2/Day 2

Covered RC circuits. I gained more experience building circuits and was introduced to creating non-DC signals (for the first time in this journey). For the project, I designed High Pass and Low Pass filters to the specifications given in the lab.

In future posts, I’ll dive into specific questions or concepts I found challenging in the chapters.

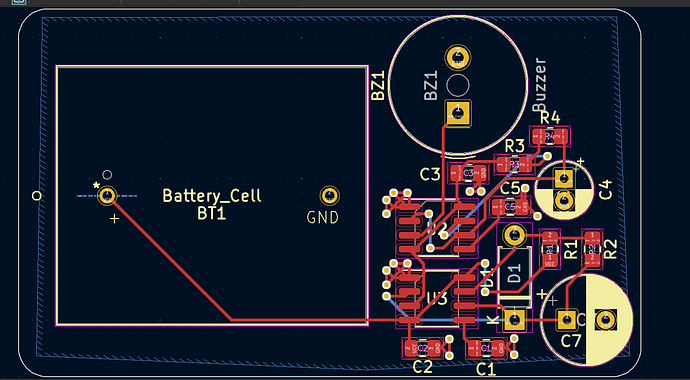

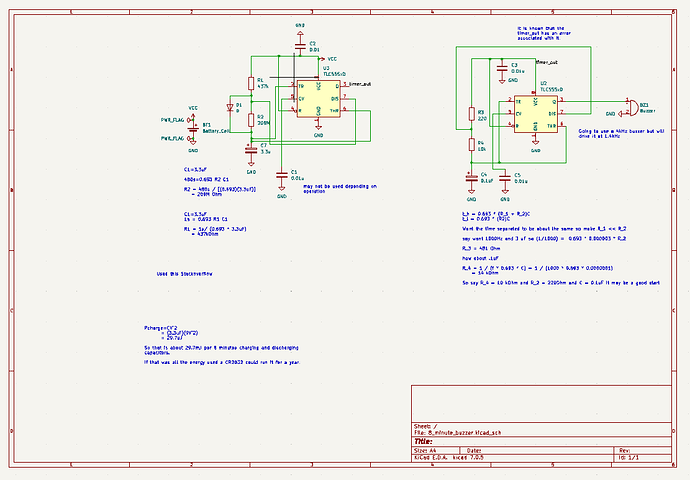

Bin Temperature Monitor

This is an ongoing project that’s currently deployed with an Arduino using the IoT cloud. However, the cables are showing wear and tear. Over the next couple of weeks, I’ll rebuild the cables and reinforce them with wire rope.

Later this year, I plan to redesign the software and hardware used to collect data from the cables. I previously attempted to design a custom board but got stuck – this is part of why I’m revisiting the basics with LAOE.

Temperature Puck

This project is on hold for now as I focus on upgrading the grain bin temperature cables and my electronics learning journey. It will likely resume sometime in November, with the goal of applying new knowledge to the data collection and app interface.

Conclusion

Apologies for this being more of a roadmap than a detailed progress report, but I haven’t updated in so long that I’ve lost track of a lot of the work I’ve done! My next updates will focus on the small projects I complete at the end of each LAOE chapter.

Thanks for reading!

![]()